AMTI Multi-Axis Wear-Testing Machines

The simulation of human joint motion, for the purpose of testing and evaluating prosthetic devices prior to clinical use, is essential to assure the successful outcome of such surgical procedures. AMTI’s multi-axis wear-testing simulator machines provide the ideal environment for in-vitro wear, fatigue, and usability testing on a wide range of prosthetic joint components.

The Multi-Axis Wear-Testing Machine can be used as a simulator solution and for research.

AMTI’s simulator products - the latest innovative developments

Activities of daily living: Increased forces and ranges of motion simulating a more real-life test, such as walking up and down stairs, getting out of a bath, bending over to pick up an object, running, and even swinging a golf club.

Virtual Soft Tissue control (VST): This software model is for the replication of in vivo kinetics and kinematics during movement using revolutionary technology (US Patent #7823460). VST eliminates the need for mechanical springs by using an advanced software model to incorporate the constraining influence of the soft tissue that surrounds the joint. This allows for the inclusion of nonlinear and asymmetric force displacement characteristics which occur in vivo but cannot be recreated with conventional methods. The VST control system opens up a number of exciting new research opportunities in simulation and kinematic study of TKR performance. Soft tissue modelling can be used to create a variety of surgical conditions such as cruciate sacrificing and cruciate sparing procedures. You can also investigate the effects of alignment, mal-alignment and ligament balance.

Adaptive Control Technology (ACT): This is a breakthrough in simulator ease of use and dramatic reduction in tuning time from days to minutes. The ACT control system is enabled by the press of a button and within 30 or 40 cycles of motion, the RMS error is reduced to a level not obtainable with manual tuning.

Improved tracking performance: in both force and displacement control modes of operation confirming to ISO and ASTM standards.

Microseparation: to stimulate laxity in the constraining tissue of the hip during the swing phase of gait.

The range of AMTI Multi-Axis Wear-Testing Machines includes:

VIVO Six D.O.F Joint Simulator

Enables more realistic biomechanics research and implant life testing. The VIVO provides accurate robotic joint motion simulation of daily activities for knee, hip, shoulder, temporomandibular, elbow, ankle and spinal joint motions.

We also supply a range of knee and hip station simulators and an ortho-pod 6 station pin-on-plate wear-testing machine.

Download the AMTI Multi-Axis Wear-Testing Simulator brochure here.

ADL-Force 5

AMTI’s single station joint simulator has recently been updated with unparalleled testing. Up to 12 different physiological motions can be sequenced to define a particular lifestyle. Orthopaedic implants can therefore be accurately evaluated under conditions that truly replicate those experienced in everyday movement. The design also allows the machine to be used as a load frame for bending, tension and compression tests.

AMTI Products

How to choose your AMTI force plate

Take a look at our list of considerations if you are interested in an AMTI force plate but not sure where to start.

AccuGait-Optimized

The AccuGait-Optimized (ACG-O) is AMTI’s portable solution for quantifying human gait and balance.

AccuPower-Optimized

AMTI’s AccuPower-Optimized (ACP-O) multi-axis force platform is a portable solution for jump, drop landing, squat analysis and more.

AccuSway-Optimized

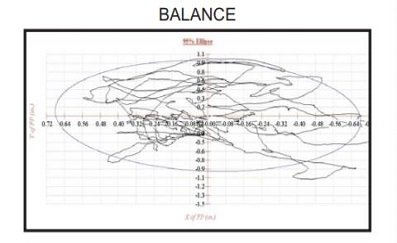

The portable AccuSway-Optimized (ACS-O) is perfect for on-the-go balance assessments and training.

Canes, Crutches and Walker Sensors

These sensors are specifically designed for the precise measurement of the forces and moments transmitted through walkers, canes and crutches.

Custom and Special Designs

These bespoke force plates are tailor-made to your requirements, including waterproof systems and glass-top platforms.

Filler Force Plates

We supply AMTI filler force plates in quarter, half and full length sizes to create the optimum custom set-up.

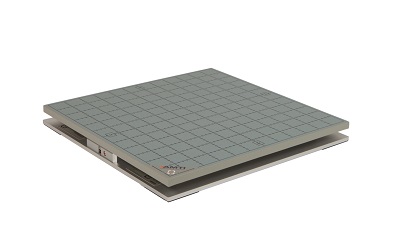

Force Plate Stairs

The force platform stairway has been designed in response to clinical patient requests to improve their gait while going up and down stairs.

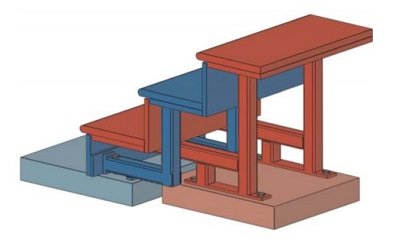

Force/Torque Sensors

The multi-axis load cells (multi-axis transducers) are ideal whenever it is important to measure forces and moments in three dimensions.

HE6x6

The HE6x6 is a compact, portable force platform for quantifying very low loads.

Mobius Treadmill

These treadmills can be with or without incline, and are a compact dual-belt end-to-end force sensing treadmill.

Optima Bio-Measurement System

The Bio-Measurement System (Optima-BMS) is Optima technology in the most affordable package.

Optima High Performance System

This ground-breaking development in force technology offers a 10-fold improvement over any other force platform available on the market.

Optima Special Purpose Series

The Optima-SPS allows activities on the top surface of the force plate to be viewed and recorded from the underside.

Portable Force Plates

Lightweight, simple and easy-to-use, including the AccuGait, AccuSway and AccuPower.

Software

We offer a range of software which can be used for data acquisition, analysis, research, rehabilitation, training and more.